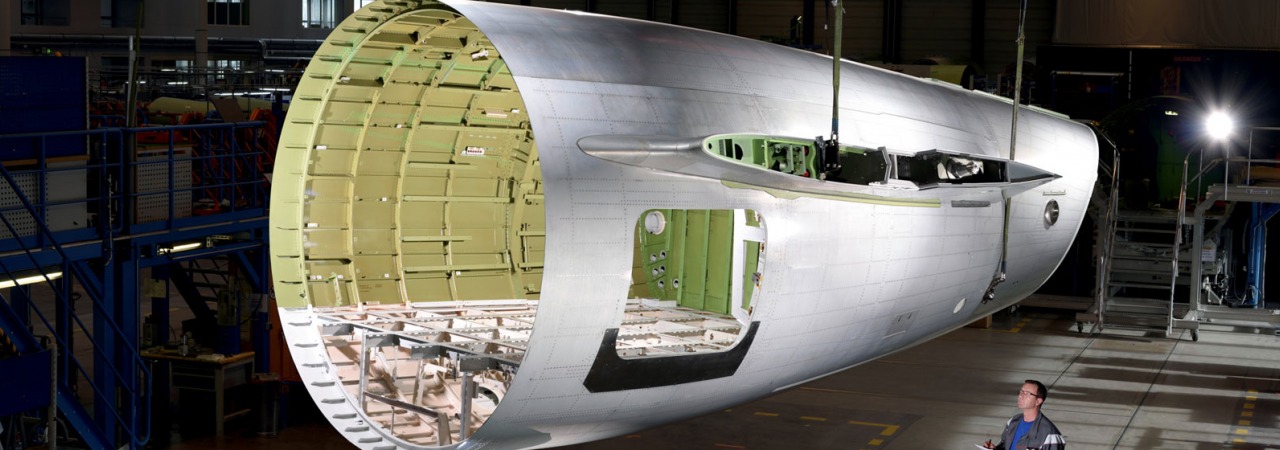

Aft Fuselage

RUAG Aerostructures manufactures the aft fuselage section of the Bombardier CRJ -700/900/1000 series. Apart from the integration of the pressure bulkhead, luggage compartment and connection for the tail planes, a special feature of this highly complex section is in particular the pylons for the engines....

RUAG Aerostructures produces the aft fuselage section of the Bombardier CRJ-700/900/1000 series from over 3500 individual parts and is responsible for the entire global value added chain. The subassemblies undergo hybrid mounting using high precision individual metal parts and carbon fibre reinforced plastic (CFRP). Among other things, the subassemblies include four complex fuselage shells. These are integrated with the floor and rear pressure bulkhead into the entire fuselage section on the main assembly line. The final aft fuselage assembly is then carried out as flow-line production across several clock stations. After the assembly of the engine pylon, all the preparations are made for the integration of the systems. The assembled section is delivered directly to the final assembly line of Bombardier Commercial Aircraft in Mirabel in the north of Montreal (Canada).